Efficiency in 3D Printing: A Greener Alternative to Traditional Methods

At Art Nzo, we are committed to reducing our environmental footprint by leveraging cutting-edge technologies and adopting more sustainable practices. Through the use of advanced 3D printing techniques and resource-efficient methods, we are constantly striving to minimize waste and energy consumption while maintaining exceptional quality in our creations.

Efficiency & Sustainability

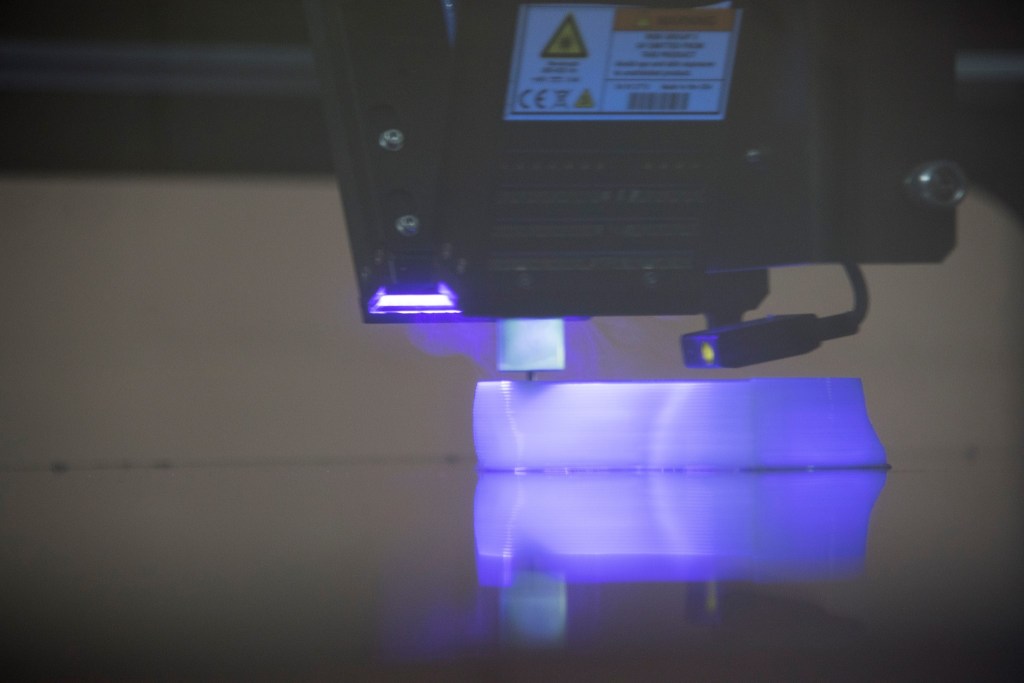

At Art Nzo, we pride ourselves on integrating advanced technology into our processes, such as the Massivit printer, which uses innovative Gel Dispensing Printing (GDP) technology. This approach is highly efficient, producing complex 3D structures with minimal waste and energy consumption. Unlike traditional methods involving foam blocks like polystyrene (EPS) or PU foam, which generate significant waste through carving or milling, our technology allows for precise use of material with virtually no excess. The gel, which hardens instantly under UV light, is applied only where needed, creating hollow but structurally strong pieces. This process reduces waste compared to methods requiring solid blocks that are later cut down, resulting in much higher material efficiency.

Material Use

While we still rely on non-recyclable materials like polyester, fiberglass, and epoxies for reinforcement and finishing, our Dimengel gel used for printing is applied directly from pots, eliminating the need for bulk transportation and storage of large foam blocks. This material usage is much more efficient, as the gel is used only as required, significantly reducing the volume needed to create large sculptures. Additionally, by creating hollow structures supported by microsupports, we ensure less material is consumed overall. This not only leads to lighter final products but also minimizes waste during the printing process itself.

Energy Efficiency

Another key environmental benefit of the Massivit printer is its energy efficiency. Unlike traditional 3D printers that require heated beds or extrusion heads for melting plastics, our printer uses UV light to cure the gel, eliminating the need for heat-intensive processes. Additionally, the high printing speed of the Massivit printer — up to 30 times faster than standard 3D printers — means that large projects can be completed in a fraction of the time, further reducing energy consumption. For instance, printing a full-scale automobile hood took only 20 hours, highlighting the printer’s ability to handle large-scale projects quickly and with less energy

Waste Minimization

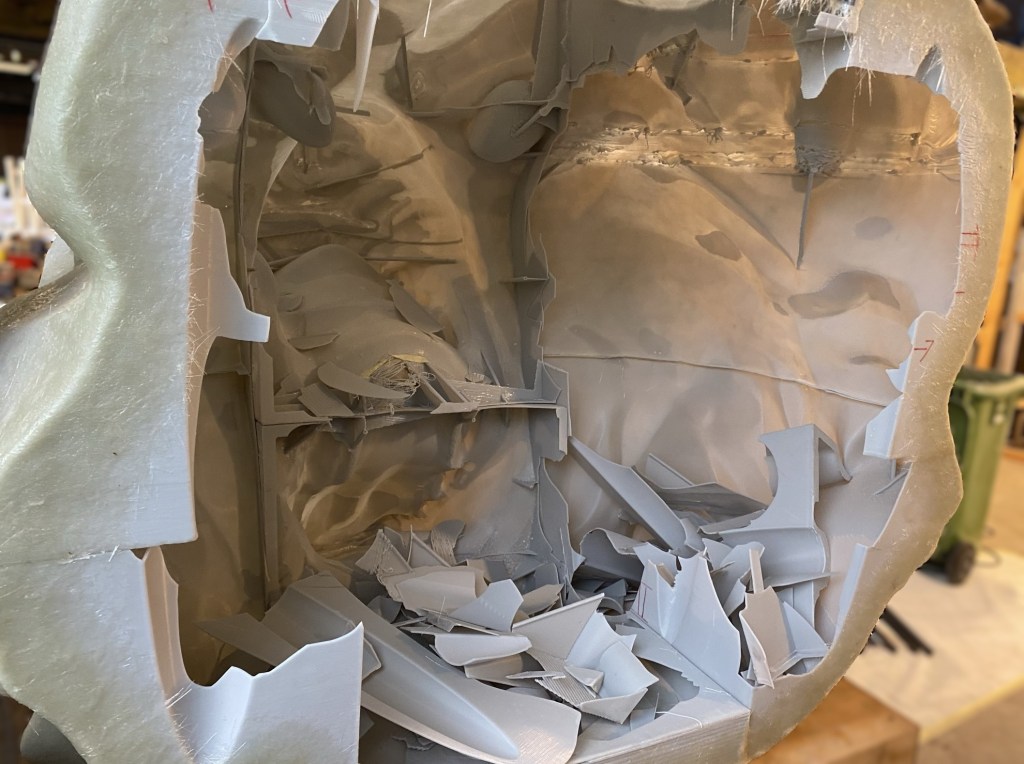

Comparing our process to traditional foam-based sculpting techniques, the benefits become clear. Techniques using EPS or PU foam blocks involve a significant amount of waste as large chunks of the material are removed during shaping. These blocks also need to be produced, transported, and stored in large quantities before being processed, further contributing to the environmental footprint. In contrast, our GDP technology uses only the necessary amount of gel, producing one-walled hollow structures that maintain strength but significantly reduce material use and weight.

Moving Forward

By leveraging Massivit’s innovative GDP technology, Art Nzo leads the way in environmentally conscious 3D printing. Our ability to create large, hollow sculptures with minimal waste, combined with the energy efficiency of UV-curing, sets us apart from traditional manufacturing methods. This approach not only reduces waste but also aligns with the Environmental criteria of the ESG (Environmental, Social, Governance) standards, showcasing our commitment to sustainability in every project. We continually assess our material choices and processes to meet high sustainability goals, ensuring that each project reflects our dedication to minimizing environmental impact while preserving artistic freedom and structural integrity.