The Hidden Vulnerability of Conventional Solutions

For many years, constructions in the creative and building sectors have relied on materials such as EPS (expanded polystyrene) and PUR (polyurethane). These plastics gained popularity thanks to their light weight, low cost, and ease of shaping. Yet they also come with serious drawbacks. Both EPS and PUR are highly flammable: when a fire breaks out, they actively contribute as fuel. This means a small flame can turn into a dangerous blaze within seconds. In addition, despite their low density, these materials are bulky and difficult to transport efficiently.

An Alternative with Proven Experience and Technique

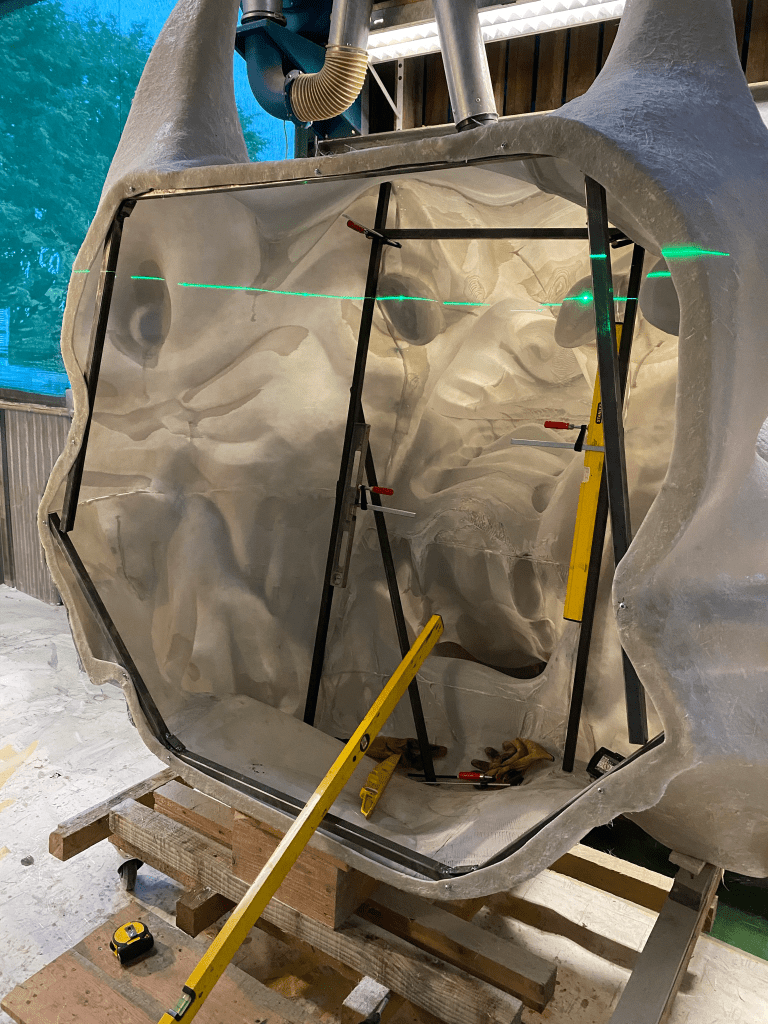

At Art Nzo, we have been working for years with 3D-printed hollow structures reinforced with polyester or mineral coatings. For us, this is not an experiment or a passing trend, but a technique in which we have built solid expertise and which we consistently apply across diverse projects. The principle is simple yet effective: by printing hollow forms, the amount of flammable material is drastically reduced. Where a solid block of EPS or PUR acts as fuel, a printed structure leaves far less mass that could feed a fire.

Finishing with polyester or mineral coatings provides both structural strength and fire-retardant properties. The result is a material solution that is not only safer to use but also highly versatile across sectors: from art and interior design to temporary installations and architectural applications.

Efficiency and Responsibility

Beyond fire safety, efficiency is playing an increasingly important role. Because 3D printing only adds material where it is truly needed, raw material consumption drops significantly. This means less waste, lower transport volume, and reduced logistical costs. Compared to conventional EPS and PUR blocks, this approach achieves a double win: both ecological and economic.

At a time when ESG (Environmental, Social & Governance) agreements are raising the bar for responsible material use, this approach is more than a technical choice: it is a step toward future-oriented business. Companies and organizations demonstrate that safety, sustainability, and efficiency do not have to be in conflict but can be combined.

Those who want to move forward can no longer cling to materials that have already shown their limitations. The combination of 3D printing and innovative coatings proves that things can be done differently: less material, less transport, greater safety. Together, we can build a new standard in which fire safety, efficiency, and responsibility go hand in hand.

Leave a comment